Microorganisms in Food Production

How bacteria and yeast are used to make food and drink

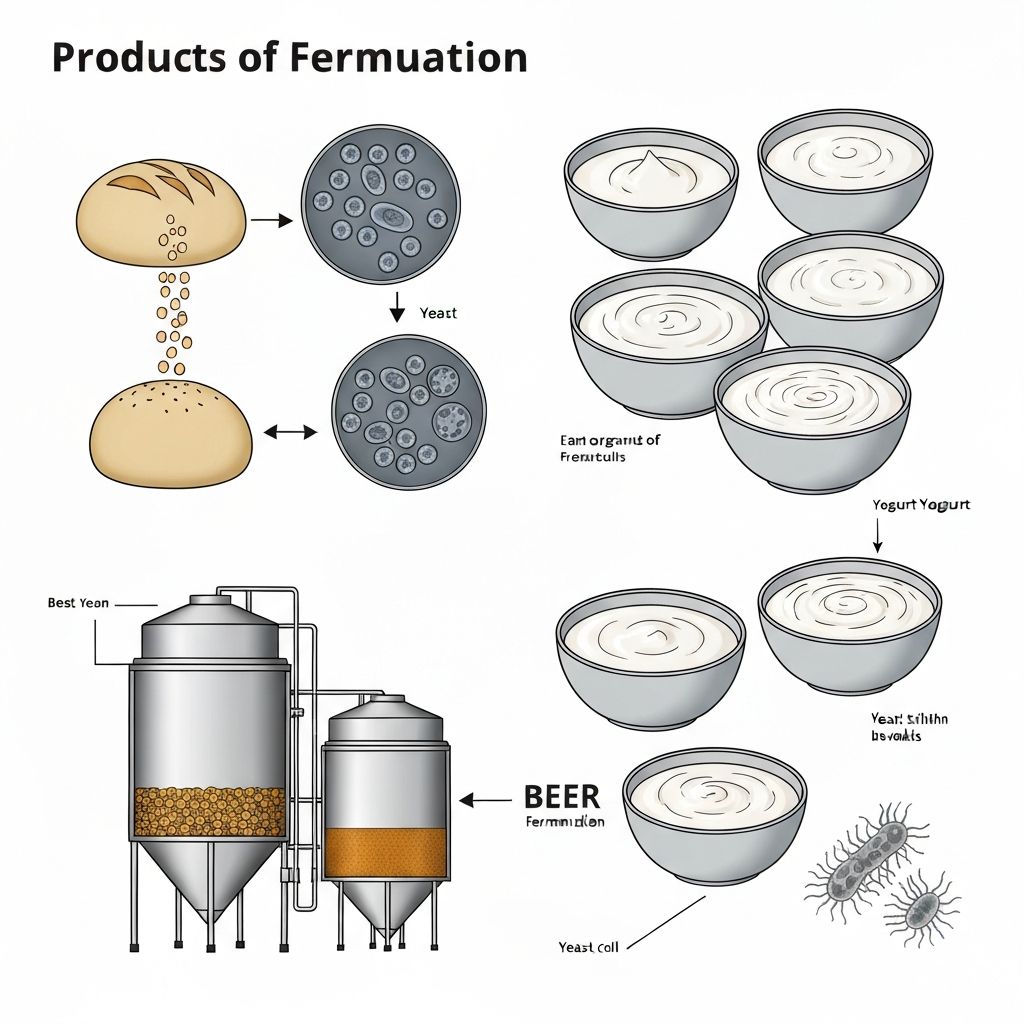

Microorganisms play a crucial role in food production through the process of fermentation. This is a type of anaerobic respiration where microorganisms break down sugars to produce useful products like acids, alcohol, and carbon dioxide.

Fermentation Process

During fermentation, microorganisms convert glucose (sugar) into other compounds without oxygen. The general equation is:

(Glucose → Ethanol + Carbon dioxide)

Dairy Products

Bacteria such as Lactobacillus ferment lactose (milk sugar) into lactic acid. This process produces yogurt and cheese, preserves the food by lowering pH, and improves nutritional content by adding probiotics. The acid also causes milk proteins to clump together, creating the thick texture of yogurt.

Bread Production

Yeast (Saccharomyces cerevisiae) is added to dough containing flour and water. The yeast ferments sugars in the flour, producing carbon dioxide gas that creates bubbles in the dough, making it rise. The ethanol produced during fermentation evaporates during baking but adds flavor to the bread.

Alcoholic Beverages

Beer and wine production rely on yeast fermenting sugars from grains or grapes. The yeast converts sugars into ethanol (alcohol) and carbon dioxide. Different yeast strains and fermentation conditions produce different flavors and alcohol concentrations.

Other Industrial Uses

Genetically modified bacteria and yeast are used to produce insulin for diabetes treatment. The antibiotic penicillin is produced by the fungus Penicillium. These industrial applications use large fermenters with controlled temperature, oxygen levels, and pH.

Safety and Control

Contamination by unwanted microorganisms must be prevented through sterilization. Pasteurization (heating to 72°C) kills harmful bacteria in milk. Temperature control ensures the right microorganisms grow at optimal rates.

| Product | Microorganism | Fermentation Process |

|---|---|---|

| Yogurt | Lactobacillus bacteria | Lactose → Lactic acid |

| Cheese | Lactobacillus bacteria | Lactose → Lactic acid |

| Bread | Saccharomyces cerevisiae (yeast) | Glucose → CO₂ + Ethanol |

| Beer | Saccharomyces cerevisiae (yeast) | Glucose → Ethanol + CO₂ |

| Wine | Yeast strains | Glucose → Ethanol + CO₂ |

Fermentation Results

Tip: Fermentation efficiency depends on maintaining optimal temperature for each organism. Yeast works best around 30°C for bread making.

Mix Ingredients

Combine flour, water, sugar, and yeast